DYES IN WATER ARE A GROWING CHALLENGE

The economical use of water as a resource in production processes has come increasingly into focus in recent years. Not only must the waste caused by improper usemust be minimized, but also the release of industrial wastewater (effluent water). Wastewater from the textile industry and from washing plants is a major contributor to water pollution.

Due to their high thermal and chemical stability, synthetic dyes remain in the environment for long periods and are not biodegradable. They therefore continuously accumulate in water - a serious problem for the environment. But it is a problem for which Clearstream can provide a solution.

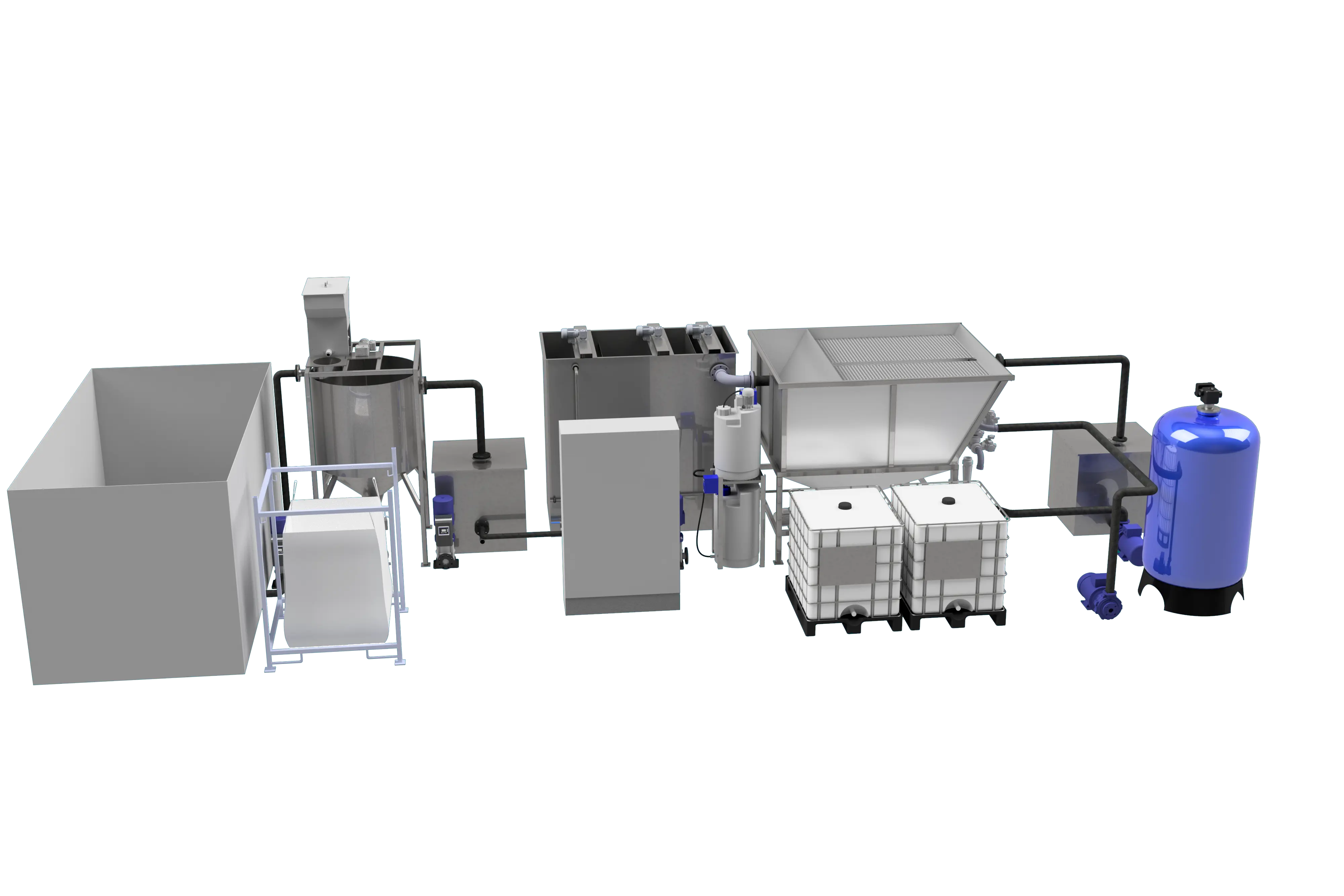

CLEARSTREAM TECHNOLOGY FOR EFFLUENT WATER TREATMENT

Clearstream’s effluent water treatment technology combines advanced oxidation processes with chemical, photocatalytic and non-chemical methods to treat wastewater containing high concentrations of synthetic dyes. It is based on a very fast chemicalbased precipitation reactor technology. This multi-stage, chemical-based wastewater treatment reliably and efficiently removes synthetic dye residues generated by all dyeing and washing processes in the textile and laundry industries. The system also offers the possibility of reusing wastewater in production processes.

WHAT IS THE DIFFERENCE TO CONVENTIONAL METHODS?

Clearstream’s effluent water treatment technology was developed specifically for the removal of synthetic dyes from wastewater. It is particularly flexible in application and allows handling of widely varying influent water parameters. Our innovative technology enables us to implement a compact wastewater treatment system for treating dye wastewater in a single 20-foot container. Thanks to the highest reprocessing efficiency, between 96 and 99% of the wastewater can be reused with additional equipment. Unlike many other systems, industry and commerce thus achieve almost zero reduction in wastewater discharge with our technology.

Our system at a glance

Benefits:

- Tragbares Systemdesign verfügbar

- Skalierbar in jeder Größe, z.B 20 m3/h (max.) Durchflussmenge

- Automatischer Systembetrieb

- Einfacher Plug-and-Play-Aufbau

- Kann entsprechend den örtlichen Abwasserbestimmungen ausgelegt werden

- Optimierter minimaler Energie- und Chemikalienverbrauch (Kosten pro 1000 Liter Reinwasser zwischen 0,10-0,15€)

- sehr lange Lebensdauer des Systems